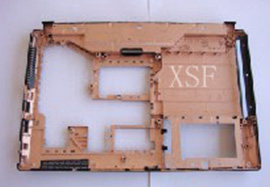

Silver copper conductive paint - computer case

Silver-clad copper anti-electromagnetic wave shielding coating is a conductive paint made of excellent conductive silver-coated copper powder by Shenzhen Xinshengfeng Technology Co., Ltd. Single component, labor saving, time saving, convenient, good adhesion, smooth, strong cohesive force, no loose particles, can be used for metal, composite materials as the substrate of mobile phones, calculators, precision instruments and other shell wall coating materials. The paint performance is stable after drying and curing, and is suitable for single-piece batch spraying factory production. At the same time, it only needs to spray a thin layer to have good electrical conductivity.

Product nature:

Conductive material: copper, silver particles

Color: silver copper (approximate silver)

Solid content (%): 38±2

Density (g/cm2): 1.1±0.05

Viscosity: 8-16s (4 cups, 25 ° C)

Resistance:<0.05 ohm / 15μm dry film

Theoretical spraying area: 5-8m2/kg

Best shelf life: the original barrel can be kept for 6 months

Thinner: BL-333

Thinner: Alcohol

Standard packaging: net weight 4 kg

Stirring and dilution:

It is easy to mix well and shake it with a shaker for 5 minutes. It is necessary to check that there is no sediment at the bottom of the barrel before it is shaken (especially when mixing with hands). Please use BL-338 thinner, the dilution ratio is 1:0.7 (volume ratio).

Spraying method:

This coating can be sprayed with conventional spraying equipment, or it can be sprayed with more advanced low-pressure and high-injection equipment, which will have better effect and save paint. It can also be sprayed with fully automatic mechanical arm.

After the spray film is dried, it should have a thickness of 15μm to have sufficient anti-interference ability. However, depending on the actual requirements of the user in terms of anti-interference, the coating film can be thinner. It is necessary to prevent dry spray when spraying, and the dry spray will cause coating. The adhesion of the film is insufficient and rough.

The surface of the spray must be clean and dry.

dry:

Naturally dry at 25 ° C. Dry for 5 minutes, dry for 2 hours

drying:

Drying at 65 ° C for 30 minutes - completely dry, after drying for 1 hour to get the best resistance.

Conductive paint features:

1) It has excellent electromagnetic wave shielding effect and electrical conductivity;

2) Excellent adhesion to plastic substrates such as ABS, ABS+PC, PC, HIPS, PS, etc.

3) Direct dilution with oil-opening water, large dilution ratio, lower customer cost, in line with the latest EU standards

4) Excellent wear resistance, high and low temperature resistance, cold and heat resistance, workability

5) Good film forming performance, no powder removal, hard and durable film